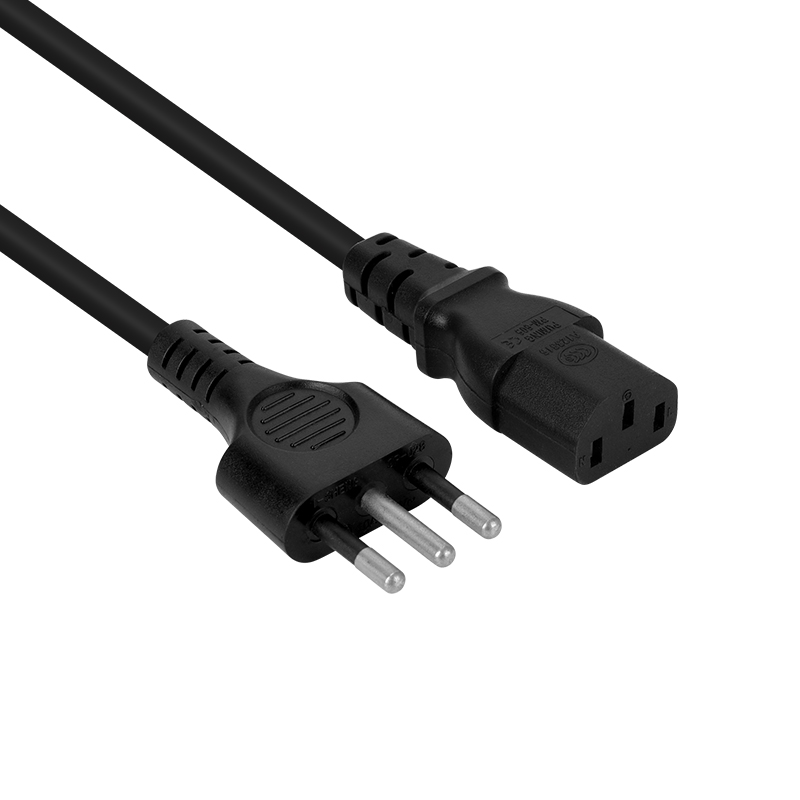

US 3Pin Plug to C5 tail power cord

Product Details

Technical requirements

1. All materials must comply with the latest ROHS&REACH standards and environmental protection requirements

2. The mechanical and electrical properties of plugs and wires must comply with the ETL standard

3. The writing on the power cord must be clear, and the appearance of the product must be kept clean

Electrical performance test

1. There should be no short circuit, short circuit and polarity reversal in the continuity test

2. The pole-to-pole withstand voltage test is 2000V 50Hz/1 second, and there should be no breakdown

3. The pole-to-pole withstand voltage test is 4000V 50Hz/1 second, and there should be no breakdown

4. The insulated core wire should not be damaged by stripping the sheath

FAQs

Yes. There're kinds of power cord, usb cable, wire harness, HDMI cable and home appliance will be the main products line of Dongguan Komikaya Factory. The OEM bulk order will be accepted as well.

Yes! You are welcome to place sample order to test our superior quality and services.

Scope of application

Instructions

1. Turn on the power of the 8681 continuity tester (power button ON/OFF is at the back of the body), the power indicator light is on

2. The input end of the test fixture inserts into the output socket of the tester, check whether the fixture is in good condition at the same time

3. The performance of the continuity tester should be calibrated and debugged by a technician before operation. The test items include: (1) Short-circuit test, continuity resistance test, insulation test, and instantaneous short/open-circuit test

4. Test parameters (refer to the requirements of the engineering drawings, if no required according to the SOP standard) Voltage: 300V

5. Number of test points: at least 64 (L/W category) (3) Test specifications: 2MΩ (4) Short/open circuit judgment value: 2KΩ

6. Instantaneous short/open-circuit test time: 0.3 seconds (6) Conduction cathodic reactance: 2Ω (L/W category

7. Start test after the quality controller confirmed that the product are qualified. Insert the rubber shell's both ends into the test socket horizontally. When the horn sounding and the green light is on, it’s judged as a qualified product, otherwise, it’s a defective product

once the red indicator light is on and the whine is heard.

8. The first tested product must be confirmed by quality controller before mass production