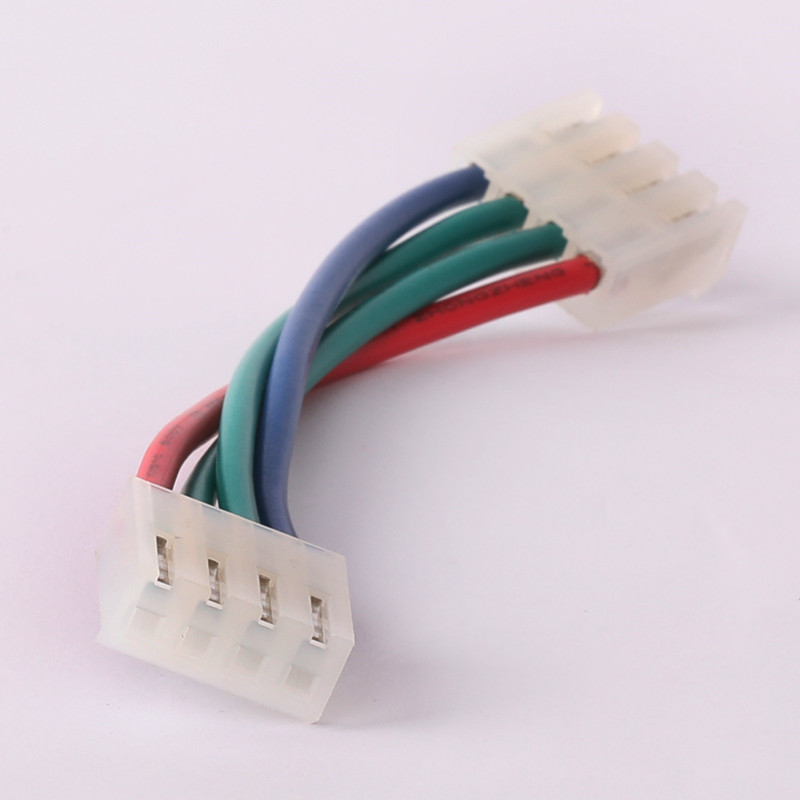

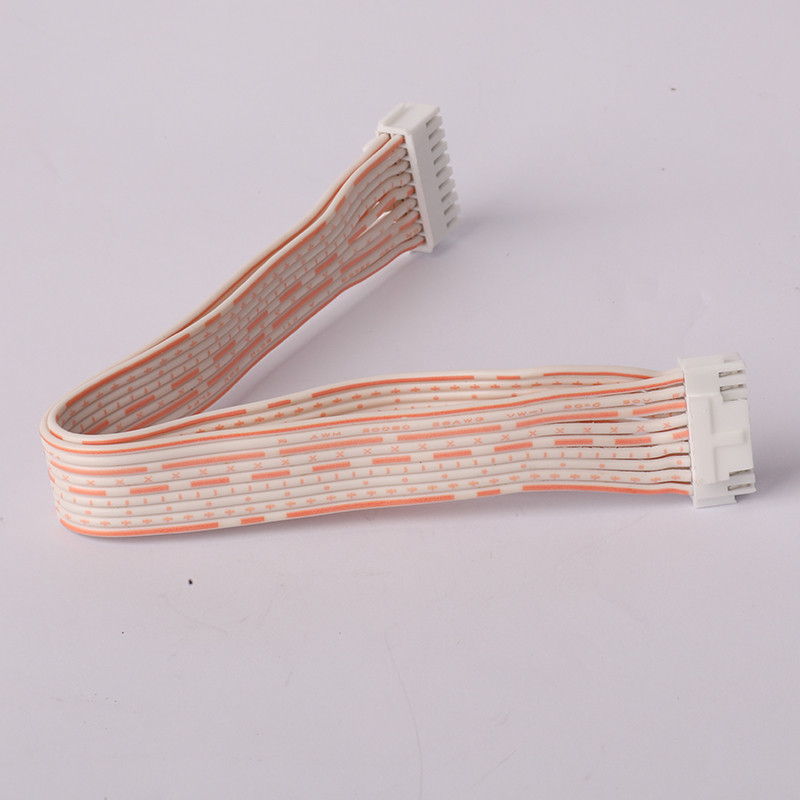

Top Quality Engine Wiring Harness - Copper conductor S9 L3 mining machine harness cable assembly – Komikaya

Top Quality Engine Wiring Harness - Copper conductor S9 L3 mining machine harness cable assembly – Komikaya Detail:

Appearance requirements

1. The surface of the wire colloid should be smooth, flat, uniform in color, without mechanical damage, and clear in printing

2. The wire colloid must not have the phenomenon of lack of glue, oxygen skin, variegated color, stains and so on.

3. The finished product size must meet the drawing requirements

Electronic Test

① Open/short/intermittence 100% test

② Insulation resisitance:20M (MIN)at DC 300V/0.01s.

③ Conductive resistance: 2.0 Ohm (MAX)

What are the important factors that affect the selection of terminal wires?

At present, the use of switching power terminal in electronic products has become a development trend, and the components of switching power terminal are slowly expanding, and can bear a larger output power. With the increase of terminal volume, the necessity of their role in the machinery and equipment becomes more and more obvious, and they play an increasingly critical role in ensuring the characteristics of goods. The following actually introduces the key elements of the selection of hazardous wiring terminals.

First, output power solution elements

One of the first factors that must be considered is the ability of the component to work with output power. There is no uniform specification for defining the output power and characteristics of terminal goods. The specifications and models of terminal blocks manufactured in Europe are IEC standards, while those manufactured in the United States are UL standards.

The difference between the two specifications is quite large. Technical engineers who do not understand the product type method run a very high risk of using components that do not reach the required output power level, or using components whose specifications far exceed the design requirements. In Europe, the current rating of a component is determined by the temperature of the metal conductor at which the current is detected. When the temperature of the metal pin is higher than 45℃ than the operating temperature, the accurate measurement personnel will use this current as the rated voltage value (or higher current) of the component. Another item in IEC specifications is the allowable current, which is 80% of the larger current. In contrast, the UL specification sets the current allowance for the component as 90% of the current when the temperature of the metal conductor is higher than the operating temperature of 30℃. It is not difficult to see that the temperature of a part of an electric conductor of metal materials is a very critical element in all its applications.

This is critical for mechanical equipment. Because the mechanical equipment generally must be in the temperature of 80℃ working environment. If the terminal temperature is 30℃ or 45℃ higher than this temperature, the terminal temperature may exceed 100℃. Depending on the type of allowance and insulation material selected for the selected components, the goods must be operated at a current less than the rated current so that they can be reliably operated within the desired temperature range. In some cases, raw materials suitable for compact packaged components will not be able to account for heat removal requirements very well, so the current of such terminal components must be significantly less than the rated current.

Product detail pictures:

Related Product Guide:

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for Top Quality Engine Wiring Harness - Copper conductor S9 L3 mining machine harness cable assembly – Komikaya , The product will supply to all over the world, such as: Cape Town, Philippines, Nicaragua, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.