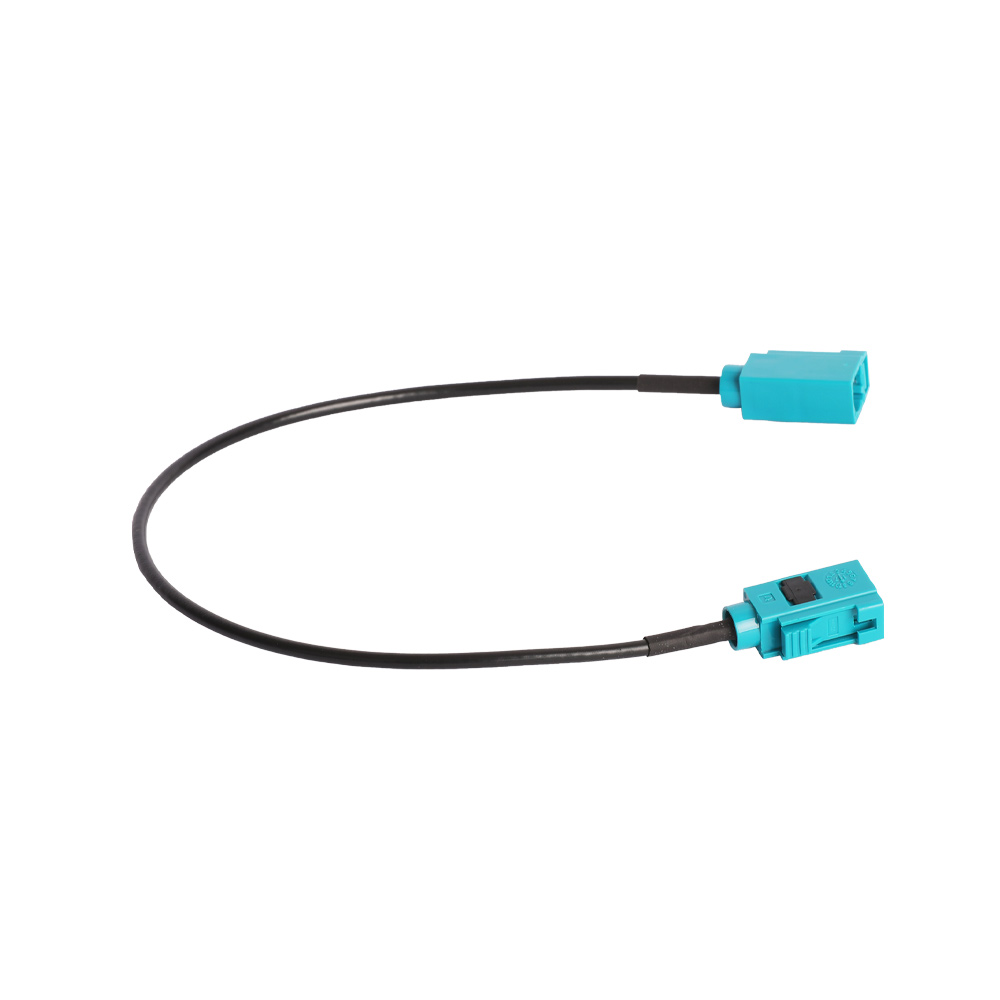

Round connector radio test automotive cable assembly china factory

Requirements:

1. Antenna SR lifting weight (5KG): ≥ 1 minute.

2. Retention force of wire and antenna terminal: ≥5.0kgf.

Retention force of antenna shell and terminal: ≥3.5kgf.

TEST:

1.a.100% conduction, short circuit, open circuit, dislocation, dielectric withstand voltage test;

b. Insulation resistance: ≥10MΩ, DC 500V, 0.01S;

c. On-resistance: ≤3Ω;

d. Withstand voltage: AC 350V I: 1mA T: 0.1S;

2. Instantaneous short circuit test time ≥ 3 seconds;

Package:

1. The appropriate number of products are tied into a bundle with PE film, and the labels should be stacked neatly.

2. The product is packed in a white transparent PE bag (the quantity is subject to the actual quantity), the width is: 324mm, the thickness: 0.06mm. (Item No.: 3040016101) The length is subject to the actual demand length, and the opening is folded in half and sealed with transparent glue. Affix the label of feige customer in the middle position.

3. The product is packed in a medium-sized carton 48.5*34*22CM H838D (part number 3010002202) (the packing quantity is subject to the actual quantity); after packing, the feige delivery label is attached to the upper left corner of the side of the outer box.

Remarks:

1. P1 end peeled 15±1mm, P2 end peeled 9-10mm.

2. The P2 end braid cuts short to 4-5mm, and the core wire is welded through the copper tube. The welding points are covered with A/B glue. Before the glue is cured, the cable tie tube should be installed. The cable tie tube is riveted and pressed against the wire. And the copper pipe bites the flower part.

3. The core wire of the P1 end should be cut by 9-10mm, and the core wire should be peeled and tinned for 5mm, and then penetrated into the terminal hole for welding. The ground wire is welded through the sleeve.