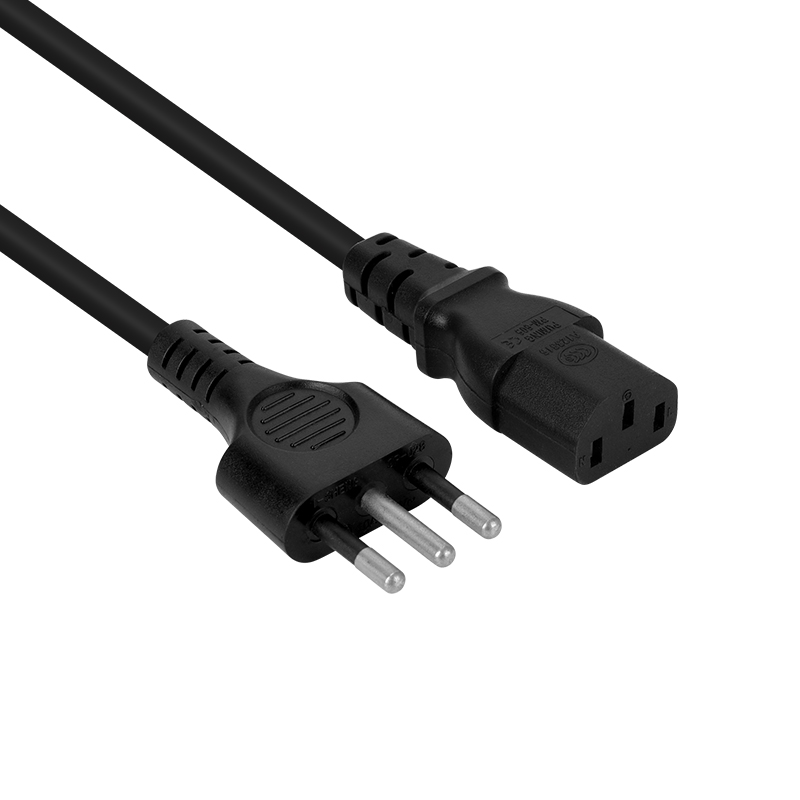

Korea 3 pin plug C13 Power cord

Product Details

Technical requirements

1. All materials must comply with the latest ROHS&REACH standards and environmental protection requirements

2. The mechanical and electrical properties of plugs and wires must comply with the ENEC standard

3. The writing on the power cord must be clear, and the appearance of the product must be kept clean

Electrical performance test

1. There should be no short circuit, short circuit and polarity reversal in the continuity test

2. The pole-to-pole withstand voltage test is 2000V 50Hz/1 second, and there should be no breakdown

3. The pole-to-pole withstand voltage test is 4000V 50Hz/1 second, and there should be no breakdown

4. The insulated core wire should not be damaged by stripping the sheath

Product application range

Power cord is use for below end Electronic equipments:

1. Scanner

2. Copier

3. Printer

4. Bar code machine

5. Computer host

6. Monitor

7. Rice cooker

8. Electric kettle

9. Air Conditioner

10. Microwave oven

11. Electric frying pan

12. Washing Mach

FAQs

We have obtained ISO9001 Quality Management System Certification, IATF16949 system certification, access to high-tech enterprise certificate, Hdmi cable with adapter, USB-IF certification, AC power cord cable obtained 3C, ETL, VDE, KC, SAA, PSE, and other multinational certification.

Yes .The order information and photos at different production stage of your order will be sent to you and the information will be updated in time.

Scope of application

Precautions:

1.During the tensile test, the rear leg of the terminal must not be riveted with insulation to prevent the rear leg from being stressed

2. The tension meter must be within the valid inspection period, and the meter must be reset to zero before the test

3. Tensile strength (tensile strength) shall be judged according to the drawing description if the customer has requirements, and shall be judged according to the conductor compression tensile force standard if the customer has no tensile requirements

Operating standard steps

1.The operator needs to check the production order and the operation flow card before starting the machine, make sure whether the indicated terminal model is consistent with the terminal installed on the machin

2.Use the mold adjusting button to manually work to see if the terminal and the die are matched, whether the upper and lower die are properly riveted

3.Test the terminal tension for the first terminal sample

4. After confirmed all the above things, fill in the first item confirmation form and notify the quality controller to check the first sample

5. After the first sample confirmed OK, start normal operation