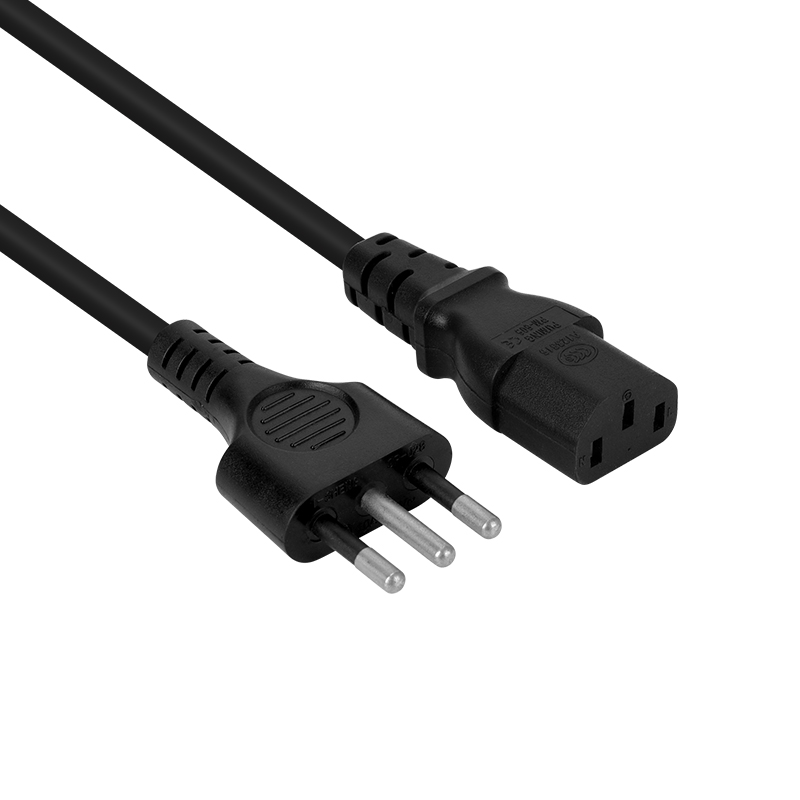

JP 3Pin Plug to C13 tail power cord

Product Details

Technical requirements

1. All materials must comply with the latest ROHS&REACH standards and environmental protection requirements

2. The mechanical and electrical properties of plugs and wires must comply with the PSE standard

3. The writing on the power cord must be clear, and the appearance of the product must be kept clean

Electrical performance test

1. There should be no short circuit, short circuit and polarity reversal in the continuity test

2. The pole-to-pole withstand voltage test is 2000V 50Hz/1 second, and there should be no breakdown

3. The pole-to-pole withstand voltage test is 2000V 50Hz/1 second, and there should be no breakdown

4. The insulated core wire should not be damaged by stripping the sheath

More introduction about this item

1. Environmental PVC material Jacket

Insulation is used outside the environmental protection of hard

Polyvinyl chloride material wire safety, wear, durable and avoid around

2. Oxygen-free copper wire core

Conductor with oxygen-free copper wire core, conductive

Good, small resistance, anti-oxidation, fast and stable transmission

3. Standard word tail socket

Universal word tail interface, the internal use of pure copper plug combination,

Resistant to plug, practical and safe

4. Plug with safety tube

The safety tube protects the safety of daily electricity

5. New tinned copper

Effectively ensure good contact with the product good electrical conductivity

6. Epidermis / Plug / Copper core

Achieve extraordinary quality

Product application range

FAQs

We are a manufacturer. All the products are factory price.

Our factory are located in Dongguan city Guangdong province of China.

You can fly to shen zhen or guang zhou international airport. And tell us your flight No. We will arrange to pick you up.

We have obtained ISO9001 Quality Management System Certification, IATF16949 system certification, access to high-tech enterprise certificate, Hdmi cable with adapter, USB-IF certification, AC power cord cable obtained 3C, ETL, VDE, KC, SAA, PSE, and other multinational certification.

Terminal work instructions

Purpose: Clarify the key points and precautions of the terminal operation

Definition: Uniform operating specifications for terminal pressure

Scope of application: Suitable for all terminal operations of our company

Duty: All terminal operators need to work according to this standard

Operating standard steps

1.The operator needs to check the production order and the operation flow card before starting the machine, make sure whether the indicated terminal model is consistent with the terminal installed on the machin

2.Use the mold adjusting button to manually work to see if the terminal and the die are matched, whether the upper and lower die are properly riveted

3.Test the terminal tension for the first terminal sample

4. After confirmed all the above things, fill in the first item confirmation form and notify the quality controller to check the first sample

5. After the first sample confirmed OK, start normal operation

Precautions

1.If you need to reach the middle of the blade during the terminal process, you must turn off the power of the machine firstly or use a steel cone

2. After emptying the terminal crimped, check whether there is any terminal stuck in the upper and lower die, to avoid overlapping double-playing of the terminals, leads to blade broken

3. Self-inspection should be done during the operation to avoid and defective products for batch production

4. If customer have special requirements, according to customer's requirments