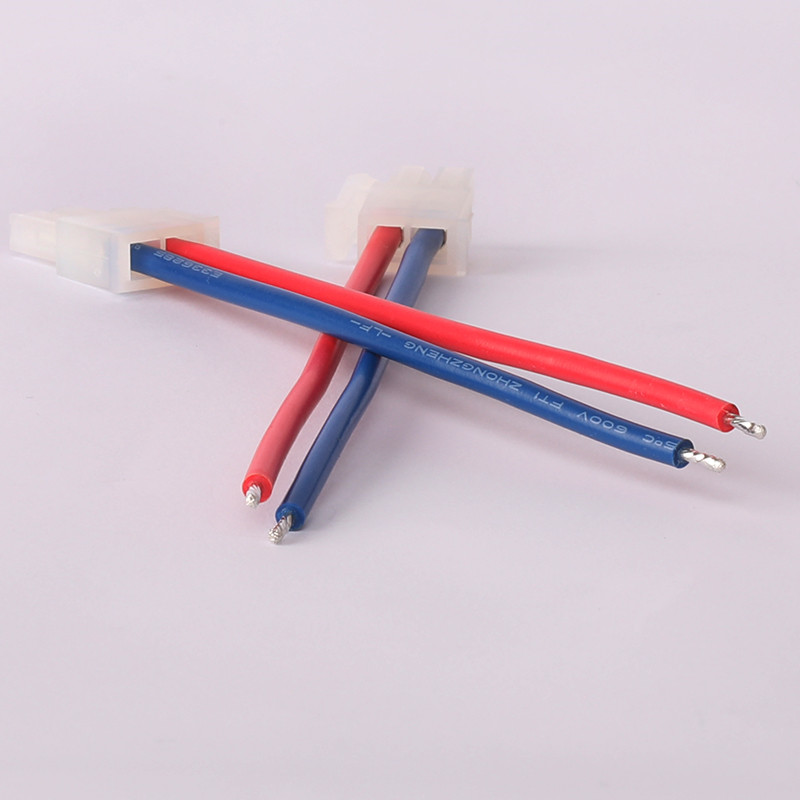

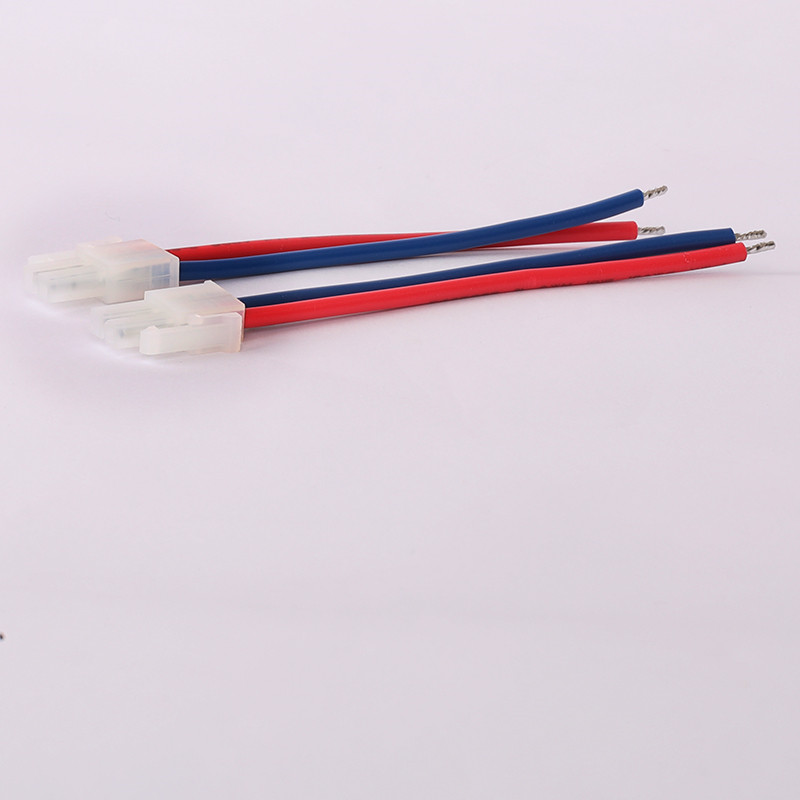

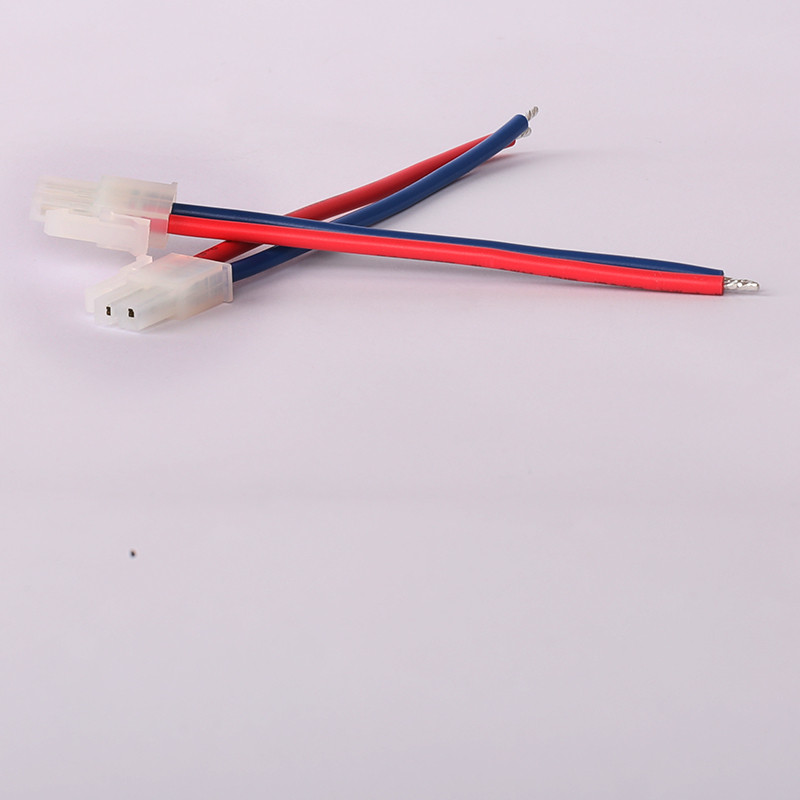

Factory supplied Main Wiring Harness - PVC material battery toy wire harness cable assembly – Komikaya

Factory supplied Main Wiring Harness - PVC material battery toy wire harness cable assembly – Komikaya Detail:

Appearance requirements

1. The surface of the wire colloid should be smooth, flat, uniform in color, without mechanical damage, and clear in printing

2. The wire colloid must not have the phenomenon of lack of glue, oxygen skin, variegated color, stains and so on.

3. The finished product size must meet the drawing requirements

Electronic Test

① Open/short/intermittence 100% test

② Insulation resisitance:20M (MIN)at DC 300V/0.01s.

③ Conductive resistance: 2.0 Ohm (MAX)

Dongguan terminal line finished product inspection packaging process steps

This article is mainly to explain the dongguan terminal line finished product inspection packaging process steps, terminal line finished product inspection packaging process steps are generally divided into the following five parts: 1. Electrical test of terminal wire →2. Appearance test of terminal wire →3. Assembly of terminal wire →4. Packing of terminal wire.

1. Electrical test of dongguan terminal wire

Use standard wire testing machine to test the performance of the crimped terminal line, such as voltage resistance, impedance, short break, etc., and flow to the next inspection procedure after checking OK.

2. Dongguan terminal cable appearance inspection

The electrical test OK terminal line finished products with light magnifying glass to detect whether there is bad, or with the naked eye to check whether some appearance is up to standard, whether the lack of accessories, etc., check OK after the flow to the next terminal line packaging process.

3. Dongguan terminal cable reassembly

The finished terminal wire that is checked OK is divided according to the requirements of the packing process, that is, the terminal part of the terminal wire is inserted into the sheath to complete the packing process of the terminal wire.

4. Dongguan terminal cable assembly

Assemble the finished products according to the direction of the loop on the terminal wire specification process drawing board, that is, bind them into bundles with tape or pull belt to complete the assembly process of the terminal wire.

5. Dongguan terminal wire packaging

Tidy the assembled terminal wires and pack them according to terminal wire specifications, such as 500PCS/ box, 50PCS/ bundle, 5 bundles/bag, 2 bags/box, etc. When filling the box with terminal wire products, seal the box mouth with the sealing machine and affix the terminal wire product label of the cable harness manufacturer. Complete the above 5 inspection packaging process, terminal products can be shipped.

Product detail pictures:

Related Product Guide:

With a sound business credit, excellent after-sales service and modern manufacturing facilities, we have earned an excellent reputation among our customers across the world for Factory supplied Main Wiring Harness - PVC material battery toy wire harness cable assembly – Komikaya , The product will supply to all over the world, such as: Vietnam, Turkmenistan, Cyprus, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.